Production & Facilities.‘Quality concrete and on time delivery, whatever may be the quantity’ is our motto, and that is how we differentiate us from the rest as the ‘Supplier of Choice’.

|

Production Facility

DMIX is equipped with the most technologically advanced state-of-the-art and fully computerized batching plants manufactured by Liebherr (Germany). Liebherr has an entirely new concept in concrete batching plant. The mixing efficiency is very high due to the way the mix components are added into the mixer. The mixing efficiency is improved by adding aggregates and cement at opposite ends. Water is added uniformly to the entire mix by a spray system.

We have a total of 6 batching plants. Once all plants are in operation, the total production capacity of DMIX will average up to 440 m3 per hour at any point of time, which is sufficient for any big raft pour.

We have a total of 6 batching plants. Once all plants are in operation, the total production capacity of DMIX will average up to 440 m3 per hour at any point of time, which is sufficient for any big raft pour.

Transit Mixers

|

We fully understand the complexities and logistics of modern-day construction, and our specialists are expertly equipped to deliver perfect concrete to you on time, every time. Dubai ready mix operates with a delivery fleet of over 70+ transit mixers with capacity of 9m3. All trucks are from Stetter, with chassis from Volvo and Scannia. Our mixers and pumps have latest GPS technology to ensure on time delivery and efficient fleet management.

|

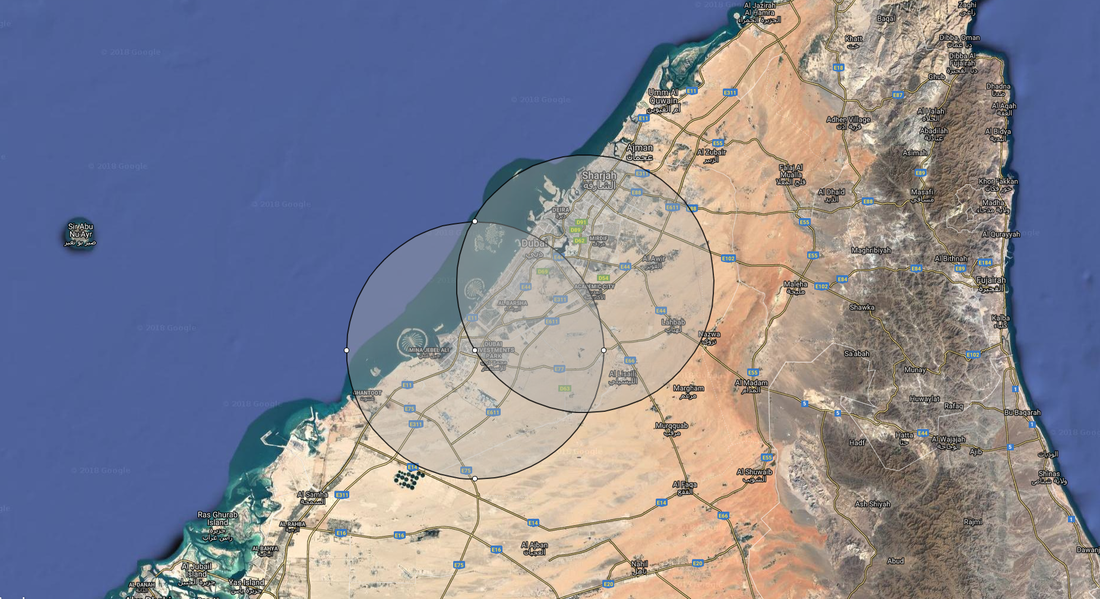

Area Coverage

|

DMIX Production Plants are strategically located in 2 major locations; Jebel Ali Industrial Area 3 between Emirates Road & Sheik Zayed Road, Dubai Silicon Oasis Authority prime location linked between Al Ain Road & Emirates Road serving the Northern Sector of Dubai.

We commit and ensure minimum transit time for concrete deliveries. |

Concrete Pumps

Temperature Control

|

DMIX has the technical know-how to control the temperature of concrete at any time, even in the peak of summer season, with the most advanced flake ice plants and chilled water units available in the market.

Each batching plant unit is supported with a dedicated flaked ice place and chilled water unit. |